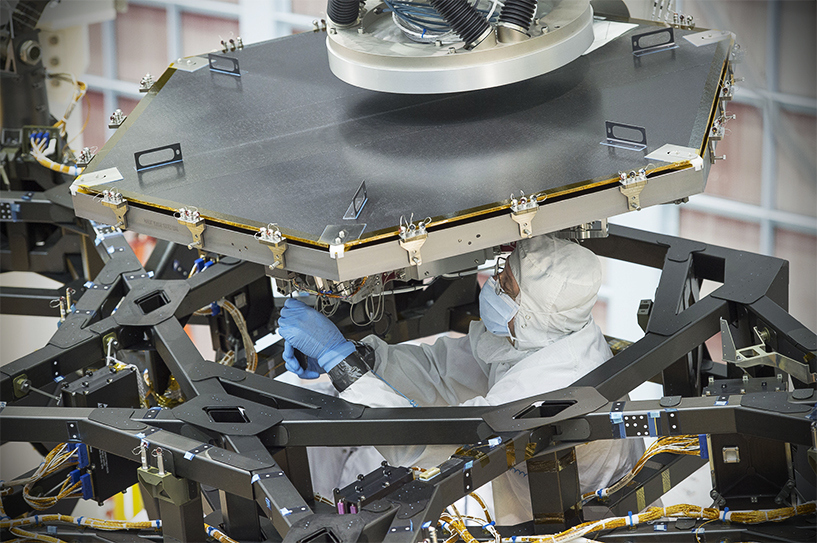

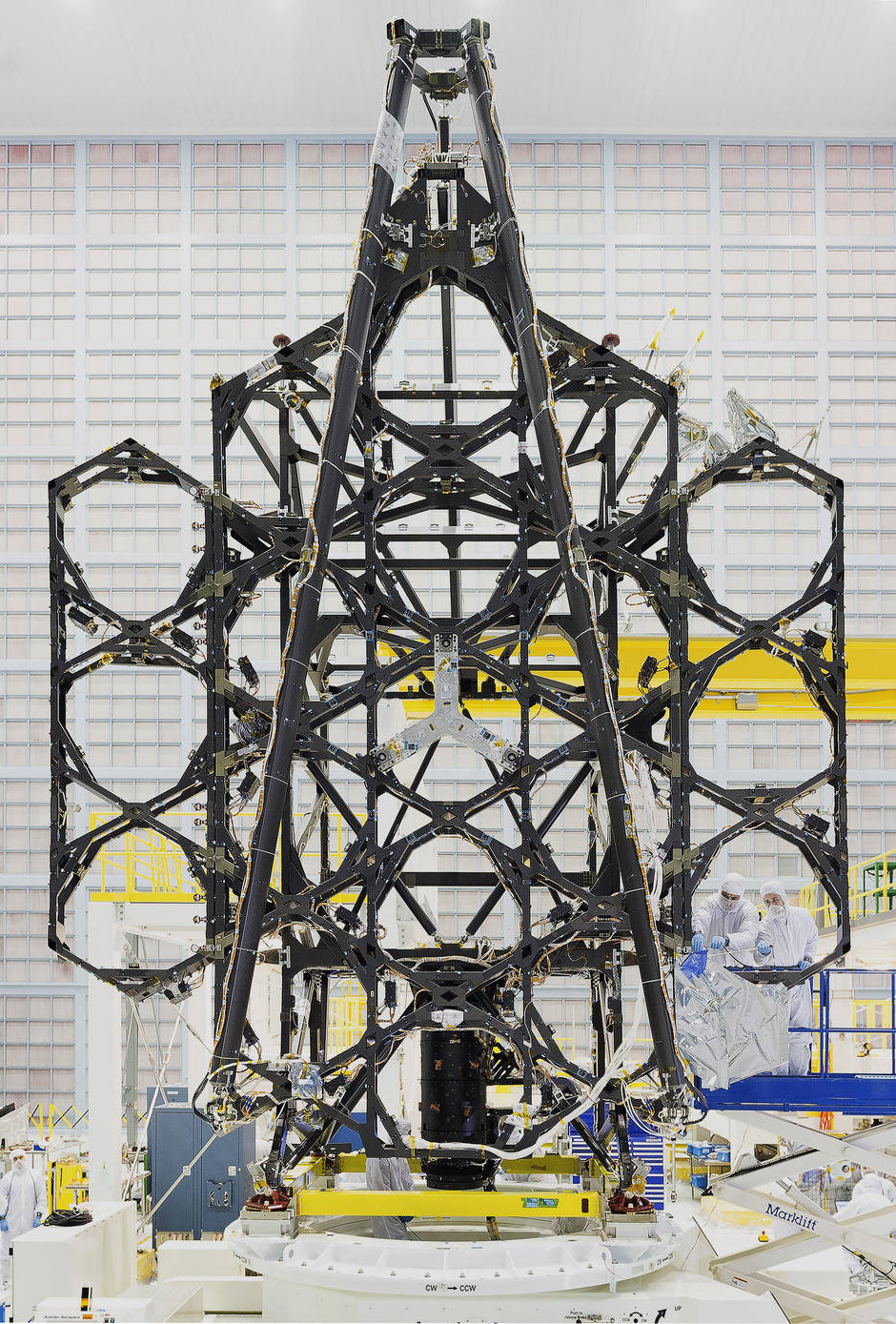

In the clean room at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, this week, the engineering team used a robot arm to lift and lower the hexagonal-shaped segment that measures just over 4.2 feet (1.3 metres) across and weighs approximately 88 pounds (40 kilograms). After being pieced together, the 18 primary mirror segments will work together as one large 21.3-foot (6.5-metre) mirror. The full installation is expected to be complete early next year.

Several innovative technologies have been developed for the Webb Telescope, which is targeted for launch in 2018, and is the successor to NASA’s Hubble Space Telescope. Webb will study every phase in the history of our universe, including the cosmos’ first luminous glows, the formation of solar systems capable of supporting life on planets like Earth, and the evolution of our own solar system.

The 18 separate segments unfold and adjust to shape after launch. The mirrors are made of ultra-lightweight beryllium chosen for its thermal and mechanical properties at cryogenic temperatures. Each segment also has a thin gold coating chosen for its ability to reflect infrared light. The telescope’s biggest feature is a tennis court sized five-layer sunshield that attenuates heat from the Sun more than a million times.

The mirrors must remain precisely aligned in space in order for Webb to successfully carry out science investigations. While operating at extraordinarily cold temperatures between -406 °F and -343 °F (-243 °C and -208 °C), the backplane must not move more than 38 nanometres, approximately one thousandth the diameter of a human hair.

“There have many significant achievements for Webb over the past year, but the installation of the first flight mirror is special,” said Bill Ochs, James Webb Space Telescope project manager. “This installation not only represents another step towards the magnificent discoveries to come from Webb, but also the culmination of many years of effort by an outstanding dedicated team of engineers and scientists.”

The mirrors were built by Ball Aerospace & Technologies Corp., Boulder, Colorado. Ball is the principal subcontractor to Northrop Grumman for the optical technology and lightweight mirror system.